THE BUILD: Modern tools and traditional techniques

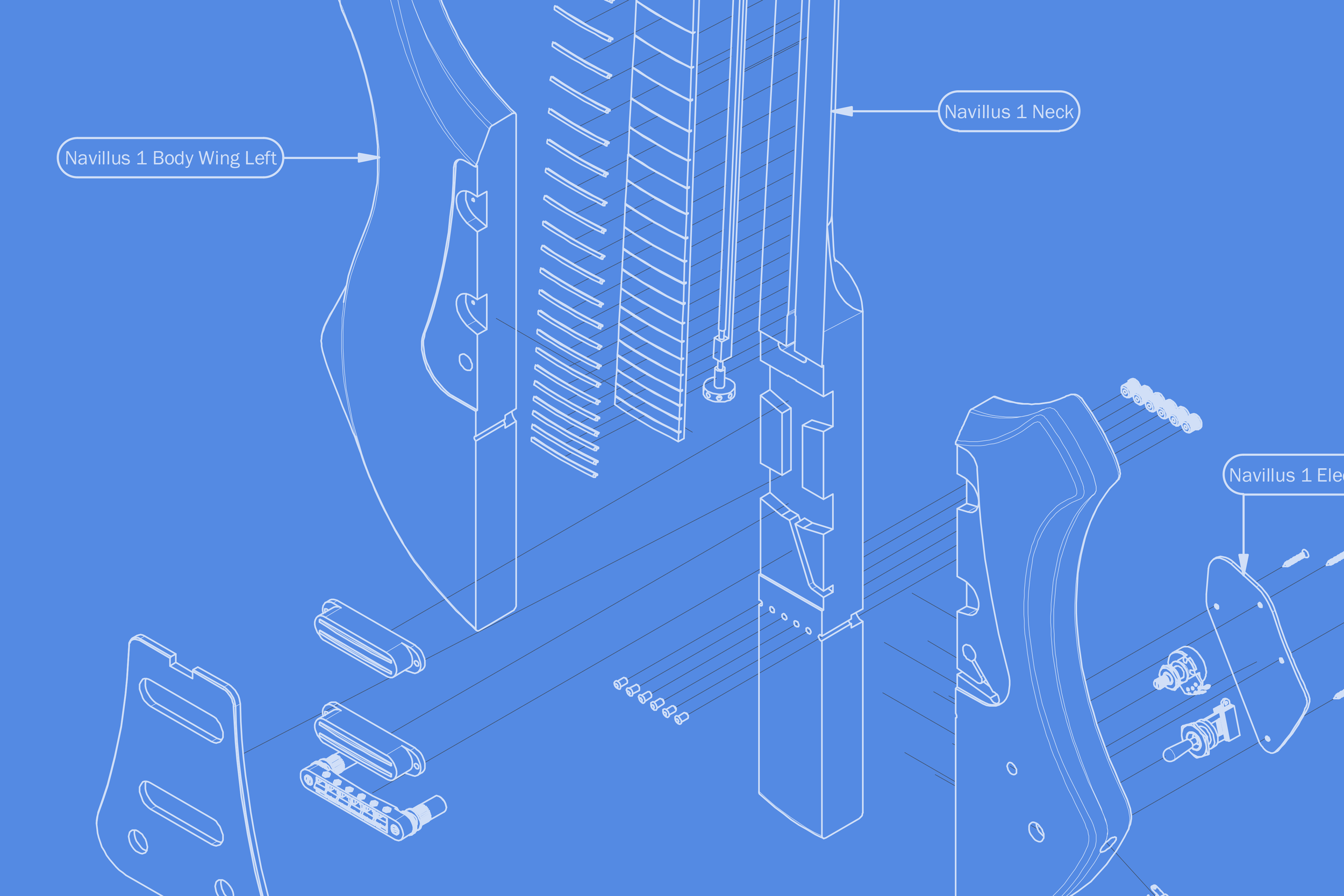

Mitchell transferred Sullivan’s hand sketch of the body and headstock shape into 3D modeling software, collaborating to develop the design-engineering and specify the details that comprise the Navillus1.

Carefully selected wood blanks are milled and laminated, then carved into components on the CNC router. Neck blank and body wings are hand assembled, then fixtured back on the router for pickup, bridge post and control pocket mortising. There are no short cuts through fretting, sanding, finishing, dressing and tuning.

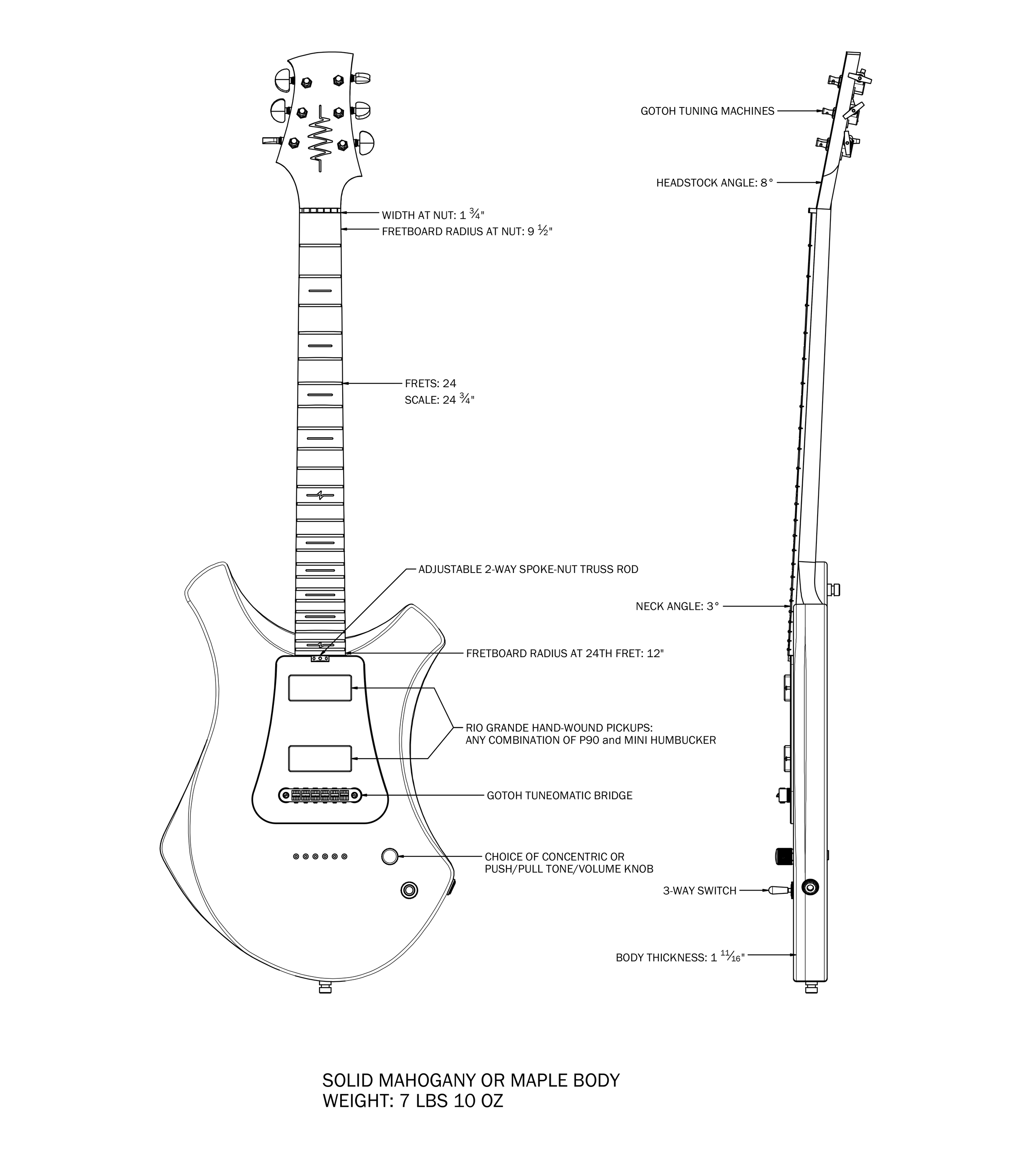

Scale, neck and headstock angles, body thickness and weight, fret size and fret board radius decisions were all informed by the best without adherence to any specific manufacturer. Combined with a furniture maker’s eye for quality hardwoods and joinery techniques, the Navillus1 looks unique without being garish and feels both familiar and modern at the same time.